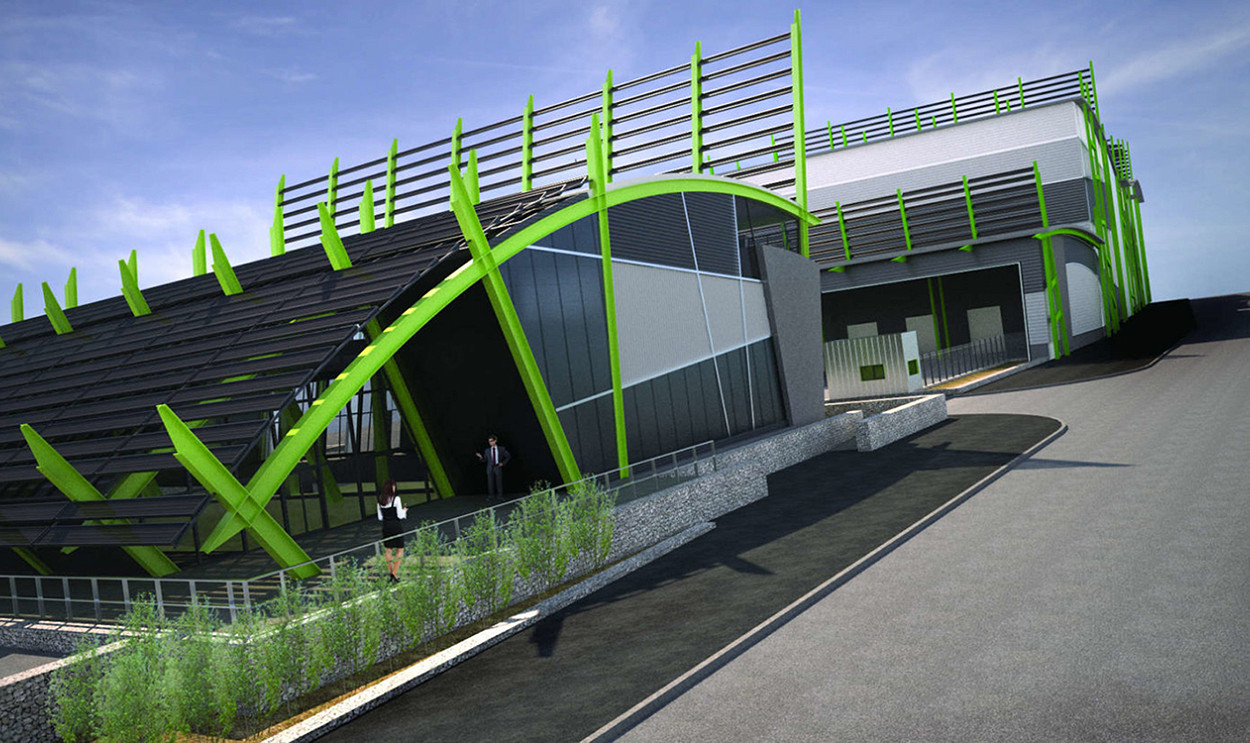

Location:Energy Works, Hull, East Riding of Yorkshire

Location:Energy Works, Hull, East Riding of Yorkshire Client:The Spencer Group (on behalf of Energy Works (Hull) Ltd.)

Client:The Spencer Group (on behalf of Energy Works (Hull) Ltd.) Architect:Elevation Design

Architect:Elevation Design Value:£200m

Value:£200m

An energy from waste facility processing up to 200,000 tonnes per annum of Solid Recovered Fuel, derived from municipal, commercial, and/or industrial sources.

The development comprises Material Recycling, In-Vessel Composting facilities and Anaerobic Digestion Plant on one site. An adjacent connected site comprises a Gasification Plant and material storage facility. There is also an Energy Academy on the site providing R&D facilities for Hull University and educational facilities to the renewable energy sector.

There was an imperative for the design teams, integrated under the management of Spencer’s D&B delivery team, to meet the demanding commercial, technical and programme delivery requirements of the project.

Critical factors were addressed and potential pitfalls mitigated, through liaison and close collaboration between all stakeholders including, statutory and regulatory bodies, client, contractor and technology providers. Project delivered on time and in budget.

The Civil and structural design addressed the site constraints including flood protection (raised structures), on-site attenuation and containment, as the site is situated next to the rivers Hull and Humber. The foundations, slabs and bases had to withstand dynamic forces from process plant and high wind loading, with the requirement for dynamic and static analysis.

The main components of the facility are, Fuel Handling Building (waste separation and grinding) with external sound wall, Balance of Plant (BOP) Building (turbine), Air Condensing Coolers, Gasifier Train and Energy Academy Building. Enabling works included River Wall repair and stabilisation and integrated drainage (SW/foul/process).

AWP designed the enabling works and the foundations, bases, slabs, bund walls and mezzanine structures for the project. The foundations were piled and designed to resist the high horizontal component of force associated with the emergency shut-down of Trommels and the high horizontal wind component transferred from the air condensing coolers. Continuous slabs were designed to resist 150kN/m2 plus point loads under the gasifier train.

Other projects